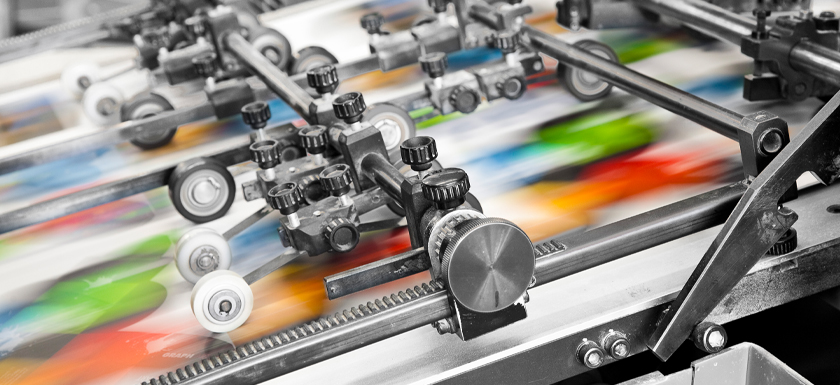

Flexo and Rotogravure Ink Solutions

Our Market Presence

With our trained personnel and advanced technology, Kolorkim Kimya San. ve Tic. Ltd. Ltd. Şti., has adopted the principle of ensuring the continuity of the trust it has established in the market and its name which has become the symbol of this trust.

Our fast service with quality, fast respond to our customers in extra color works, along with the samples from our supplier companies to perform testing procedures without losing time are among the features that stand out in the sector.

We have been serving to the market since 2001 with our flexo and rotogravure ink solutions that we produce specially in the packaging sector in our 10.300m2 production facility in total, and we are proud and glad to contribute into the economy of our country by exporting up to 70% of our products.

What is the difference in the market as the Kolorkim family that produces solvent-based printing inks, additives and lacquers for flexo and rotogravure machines?

Our quality, fast service, fast respond in non-catalog extra color works in our pantone catalog or demanded from our customers, samples from our supplier companies being subjected to testing without lose of time, the trust we have created in the market and this trust enabled the creation and sustainability of this symbol of trust in the industry for 19.

Inks produced for flexo and rotogravure printing machines are applied to certain materials, including flexible packaging materials such as Paper, cardboard, aluminum foil, OPP, CPP, PA, LDPE, HDPE, Chemical Pet, Physical Pet, PVC, PVC Shrink, Pearlize packaging. In aluminum foil applications, under-printing lacquer is applied to the floor before ink printing Moreover, heat-seal lacquers are applied allowing the foil to adhere to materials such as PS, PP, PET or PVC. Such lacquers are also produced. Release lacquers enable the protection bands to be opened more conveniently compared to the profiles. We provide assistance for our customers upon requests.

Our Customers are Our Solution Partners

Flexo or rotogravure?

Lamination or overprinting?

Which material should it be applied to?

Which criterion is the reason for preference, such as high lamination resistance, heat resistance, high color strength, abrasion resistance, water resistance, deepfreeze resistance, drying time, late drying time, etc.

All of this helps us determine which series of ink to offer to our customers in line with their demands. Having this information before sales enables us to offer the right product to our customers that we consider as our solution partners. Consultation with our solution partners at each and every stage of the process is a factor in minimizing the possible errors to be made.